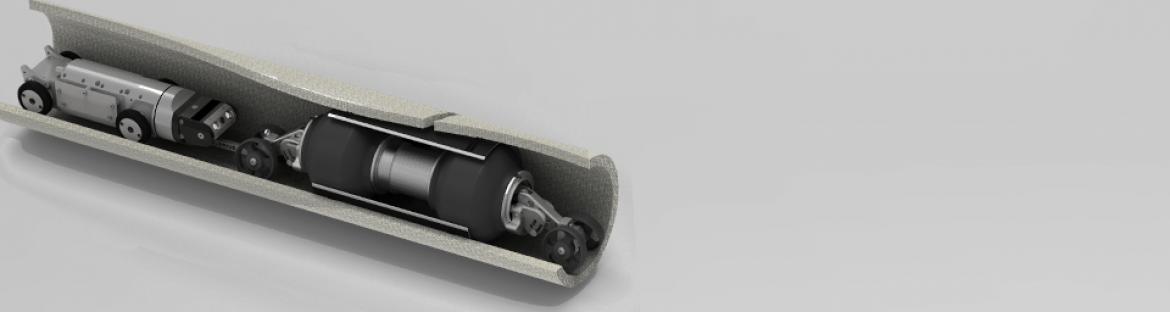

Spot Repair and Pressure Testing Packer

QLP160 - 8"-12" (200-300mm)

The QLP160 is a 2-in-1 packer for installation of mechanical spot repair sleeves and pressure testing of joints and repairs. The packer could be attached to any CCTV inspection robot, including the SR-Series CAM160 module to load repair sleeves from inside the pipe and install them. After the installation of a spot repair the integrity could be verified by pressure testing with the same packer.

Loading repair sleeves inside the pipeline

The QLP160 features pneumatic retractable front wheels for loading sleeves by driving through and partially inflate the two bladders.

After loading, the repair sleeve is positioned by driving the transporter. Once in place, the bladders are inflated and the repair sleeve installed.

Pressure testing

The space between the two bladders of the QLP160 can be exptended to perform pressure tests to verify joint connections and installed repair sleeves.

Easy to use and certified software

The QLP160 2-in-1 packer can be operated from an independant control unit or from the ID-RIS software when using the SR-Series. The control software is easy-to-use and compatible with NASSCO PACP certified WinCan and POSM software to include test results in the inspection report.

Contact ID-tec or your local distributor for more information!

Download brochure